GlebusAlloys Poland produces G-METAL™, a unique, self lubricating material for wear surfaces. Our designs can be customized to fit your needs.

Shapes

The material can be formed into many shapes and sizes including wear plates, rolled bushings, cylindrical bearings, spherical bearings, split bearings, sleeves, liners, guides and other customizable shapes. A patented conical wear plate is also available for certain industry applications.

Alloys

A variety of alloys can be formed with G-METAL™ material. Bronze, nickel, iron, iron/nickel and lead can be produced with the lubricants graphite or graphite, molybdenum, UNLIKE GRAPHITE PLUGGED BRONZE, THE MATERIAL KEEPS ITS SELF LUBRICATING PROPERTIES DURING THE ENTIRE WEAR LIFE CYCLE OF WHATEVER PART IT IS FORMED INTO.

Dimensions

G-METAL™ cylindrical bearings can be made from 8 mm to 280 mm in diameter. Rolled bushings can have a minimum inner diameter of 20 mm and a wall thickness starting at 1.5 mm. Wear plates can be produced with maximum surface dimensions of 500 mm x 250 mm x 40 mm.

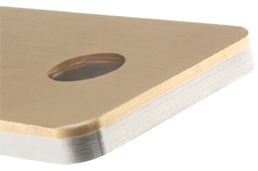

Bi-Metallic Option

To increase strength and reliability, G-METAL™ can be laminated to a steel or stainless steel backing. Manufactured by a continuous hot rolling sintering technology, the reliability and service life is greatly increased compared to conventional wear material. This bi-metallic form of G-METAL™ is available in many shapes and sizes. While wear plates are the most common, the material can also be used for bushings, bearings and other applications.

replica watches bentley breitling

montblanc boutique toronto replica

breitling navitimer world fake